Understanding Active vs. Passive Fall Protection

When it comes to jobsite safety, one of the biggest challenges is deciding between active vs. passive fall protection. Active systems require the worker to deploy and use the equipment — whether it’s a harness, lanyard, or restraint system. Passive fall protection systems protect everyone in the area without any action required by the worker, like a safety rail system.

“No one likes to be on a leash,” says Deb Hilmerson, President and CEO of Hilmerson Safety. “Workers want to do their jobs with both hands free, not constantly worrying if what they’re tied off to is actually engineered to save them.”

Active fall protection relies on the worker to do everything right: wear the harness correctly, connect to an engineered anchor point, and trust that the equipment will hold in a fall. Passive systems, on the other hand, are engineered into the jobsite so the hazard is eliminated from the start.

| Active Fall Protection | Passive Fall Protection | |

|---|---|---|

| Requires worker action | Yes | No |

| Protects one person | Yes | No |

| Protects everyone in zone | No | Yes |

| Requires constant inspection | Yes | Minimal |

| Reusable long-term | Sometimes | Always |

| Common examples | Harness, retractable, lifeline | Guardrails, barriers, parapet clamps |

Why Passive Fall Protection Changes the Game

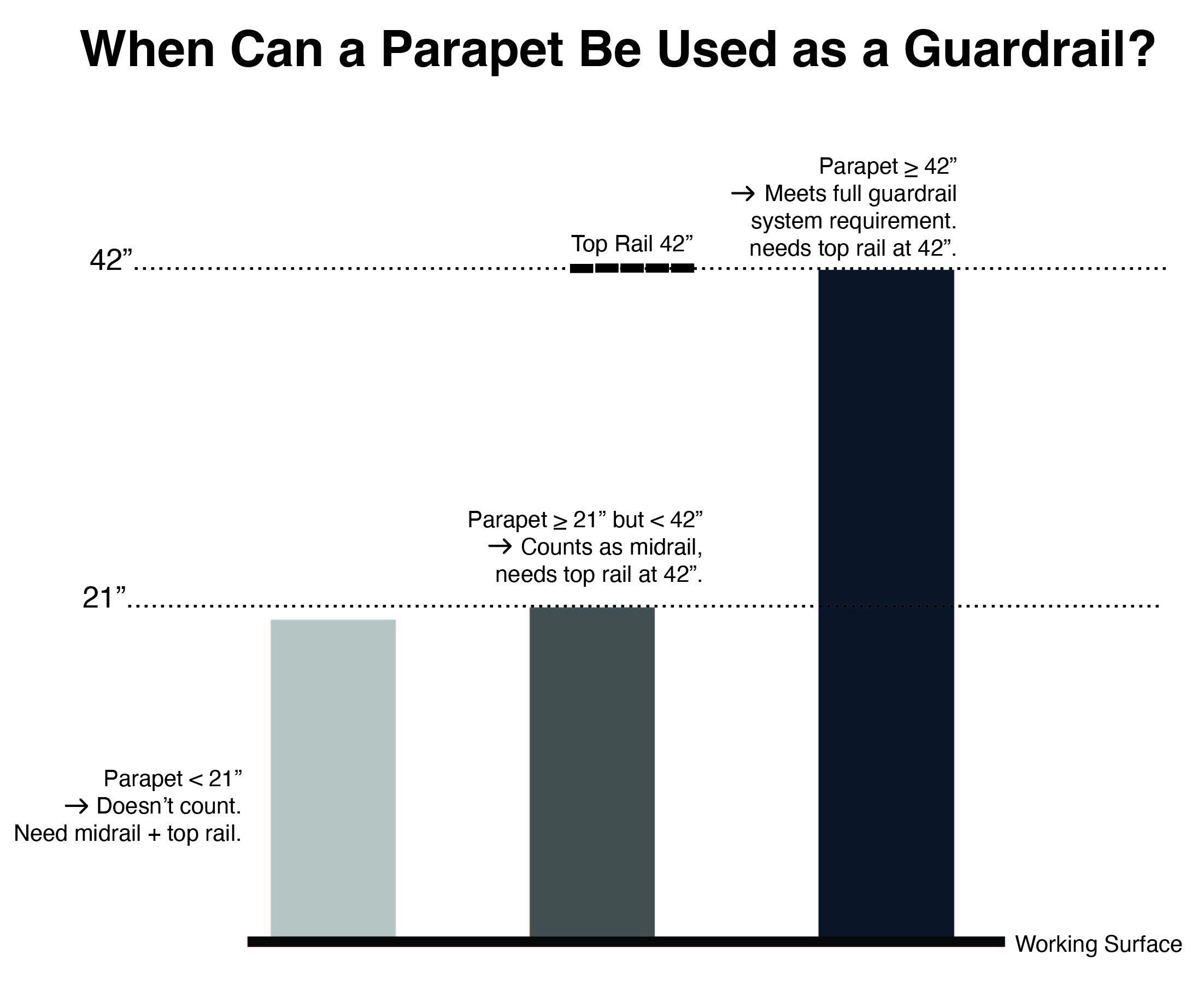

Pre-planning your project for passive fall protection solutions like perimeter guardrails, parapet clamp guardrail systems, or temporary edge protection eliminates the need for tie-offs and retractables. These systems prevent falls rather than reacting to them.

Passive systems eliminate those distractions that lead to bad decisions and unsafe behavior. Workers don’t have to unclip “just for two feet,” trip over taglines, or second-guess whether their retractable is long enough or if they’re tied off to the right point.

They can take pride in their work and focus on doing the job well — not on whether they’re about to make a life-or-death mistake.

Connecting Active vs. Passive Fall Protection to the Hierarchy

The conversation around active vs. passive fall protection is part of a bigger picture — the hierarchy of fall protection.

OSHA’s hierarchy of fall protection starts with elimination. If you can engineer the hazard out, that’s the goal. If you can’t, then you protect against it.

Most people think there’s no way to eliminate the hazard. There is — it just takes time, planning, and a little money.

Sure, installing guardrail systems around an entire building costs more upfront than handing out a harness and a retractable. But that harness only protects one person. A passive system protects everyone — and it’s reusable.

“To be more efficient and give people a proper work environment, remove the need for them to ask, ‘Did I connect to the right point?’ That’s the goal.”

Every safety professional knows the hierarchy is supposed to guide how we protect people from falls, yet too often, the industry flips it upside down.

That’s why we revisited it in our Construction Safety Week feature, “The Hierarchy of Fall Protection: Working from the Top Down.”

Because when you look at the data, it’s clear we’ve still got work to do.

“Falls are still the largest cause of fatalities in construction. It’s good that we dedicate time to it—but we should do more. The stats are still bad. In fact, they’re horrible,” says Deb Hilmerson, President & CEO of Hilmerson Safety.

The hierarchy reminds us that the first step isn’t about harnesses or lanyards — it’s about eliminating the hazard altogether. If we can’t remove it, we engineer around it. Only after that do we rely on active systems and PPE.

“You give everybody a harness and you think that’s safety,” says Hilmerson. “That doesn’t work. That doesn’t eliminate anything.”

Passive systems—like the Hilmerson Safety Rail System™—sit near the top of that hierarchy, where protection should begin. They’re engineered solutions that isolate workers from hazards instead of depending on them to make the right call every time.

So before you grab another retractable or check another harness, take a look at where your fall protection plan starts. If it’s at the bottom of the hierarchy, you’re already behind.

The Competency Gap in Active Systems

Another issue in the active vs. passive fall protection discussion is the competency gap. Active system deployment requires a competent person to be able to identify and have the authority to correct hazards, but many workers (and supervisors) lack full understanding of different systems — restraint vs. arrest, vertical vs. horizontal lifelines, etc. You don’t always get a second chance to get it right. Without proper training, a single mistake in system setup can have irreversible consequences.

If you set up a passive system — guardrails, clear zones, defined edges — you don’t have to rely on someone making the right decision every time. Keep it simple and safe and just tell the crew: stay inside the rails.

Fewer Distractions Mean Safer Work

Think about an electrician. They’re already working in a potentially hazardous environment. Add fall protection to the mix and now they’re juggling two hazards at once.

If you can remove one — say, by using guardrails instead of a harness — they can focus on what they’re actually there to do. Fewer distractions. Better work. Safer day.

Why Manufacturers Push Active Systems

The reality is that active systems dominate because they’re profitable. Major manufacturers make recurring revenue from selling harnesses, retractables, and lanyards — gear that wears out and expires. Guardrails, once purchased, can last for years.

“If manufacturers truly cared more about safety than sales, they’d be pushing passive systems harder,” Hilmerson says. “But they make a lot of money on active gear.”

This profit model has created an industry bias toward active protection — even when passive solutions could prevent more accidents.

When Active Fall Protection Is the Only Option

There are times when active fall protection is necessary.

Structural steel erection, precast installation, and similar work often involve conditions where no anchorage or floor system yet exists. In those cases, horizontal lifelines, beam clamps, or temporary anchors are unavoidable.

Even then, engineering can reduce exposure. Assembling as much as possible on the ground and flying it into place with a crane limits the number of workers exposed to height hazards.

“If you don’t have to be 200 feet in the air, don’t be,” Hilmerson says. “Build it on the ground and fly it into place. That’s what we’re supposed to be doing as safety professionals.”

When Active Systems Are Justified:

- Steel erection with no permanent structure.

- Precast installation before floors are set.

- Maintenance work on existing buildings where guardrails aren’t practical.

Pro tip: Keep active use short-term and engineer a passive system as soon as possible.

Active vs. Passive Fall Protection: The Bottom Line

OSHA’s standards haven’t changed — but the mindset on jobsites needs to. The choice between active vs. passive fall protection should always start with elimination and engineering, not convenience or cost.

Passive fall protection systems aren’t just safer; they’re simpler, more efficient, and reduce the daily strain on workers. When contractors plan ahead and commit to engineering safety into the build, everyone wins — from the superintendent to the newest apprentice.

Active vs. passive fall protection isn’t a debate — it’s a hierarchy. Passive systems prevent falls; active systems respond to them. The more we engineer hazards out of the equation, the more people go home safe. You don’t get a second chance at a fall. Plan it right, build it safe, and let your crews work without fear.

About Hilmerson Safety

Hilmerson Safety® is a full-service safety product design and manufacturing company serving the construction industry. Since 2001 Hilmerson Safety® has been working with construction industry leaders and contractors to develop safe, lean, construction-grade™ products and solutions that add to the company’s bottom line.

For more information email us or call (952) 239-0125