Why In-House and American-Made Safety Solutions Matter More Than Ever

Let’s be real – things are unpredictable out there. Contractors are navigating unpredictable pricing, material shortages, and ever-changing tariff regulations. For many, it’s not just about staying on budget—it’s about staying in business.

“Small companies don’t have the financial backing or the attorneys to fight a $5 billion GC,” says Deb Hilmerson, President & CEO of Hilmerson Safety. “And even if that contractor could be fair or flexible, they’re not usually willing to take the loss. That’s just not how the system works.”

It’s a reality that puts small to mid-sized contractors in a tough spot. They’re on the front lines, balancing razor-thin margins, labor shortages, and an unstable supply chain. When global policy shifts or tariffs hit overnight, they’re often the first to feel the squeeze.

The Tariff Tension: A Growing Risk in Construction

As outlined in the Associated General Contractors (AGC) of America’s Tariff Resource Center, contractors are now operating in a high-risk environment shaped by both enacted and threatened tariffs. On materials critical to the industry—like steel, aluminum, copper, and lumber—tariffs can significantly drive-up costs and delay projects.

As of April 2025, all goods entering the U.S. are subject to a baseline 10% tariff, with much steeper rates on imports from key manufacturing hubs: China (34% with negotiations as of April 9 at 104%), Vietnam (46%), and the EU (20%), among others. Steel and aluminum products have been particularly affected, with the U.S. government reactivating broad-based tariffs and removing earlier exclusions. Notably Bloomberg cited the U.S. is preparing to raise duties on Canadian softwood lumber (34.45%).

This has a cascading effect across the industry. Contractors face price hikes not only on imported goods but also on domestic materials, which rise in response to increased demand. It’s a double bind that leaves many builders caught between budget expectations and real-world costs.

“Tariffs don’t just raise prices—they create uncertainty,” Hilmerson explains. “And in construction, uncertainty is expensive.”

According to Hilmerson Safety research from 2017, the average cost of job-built wooden guardrails can be as high as $18.58/linear foot—and that’s before factoring in price surges from lumber shortages or changes in trade policy. Without pricing flexibility in contracts or a strategy to mitigate these risks, contractors are left absorbing costs they never anticipated.

Mitigating Risk by Taking Control of the Supply Chain

1. Shift Critical Safety and Operations to the U.S.

So how do construction firms protect themselves? One way to gain control is by shifting critical safety and operations functions to U.S.-based production and oversight.

For Hilmerson Safety, this approach isn’t new—it’s the foundation of their product philosophy.

2. Own the Equipment You Rely On

Another powerful way to take control of your supply chain? Own the equipment you rely on.

Instead of repeatedly renting and dealing with availability issues, construction firms are shifting toward owning durable, reusable systems. This not only reduces long-term costs but also ensures that essential safety equipment is always on hand—no matter the market conditions.

“Bringing production in-house isn’t just a business decision—it’s a long-term strategy,” says Hilmerson. “It gives us the control to innovate, respond to market changes, and maintain quality without compromise.”

By investing in durable, reusable safety solutions that are engineered, manufactured, and distributed in the U.S., Hilmerson offers customers a way to avoid repeated purchases, reduce labor costs, and ensure availability, regardless of what’s happening overseas.

When you control the process, you gain more than efficiency—you gain predictability. That’s a game-changer in today’s volatile environment.

Born in the Field. Made in America. Built to Last.

Hilmerson Safety’s commitment to American-made products is more than a tagline—it’s a promise backed by two decades of experience and real results on job sites across the country.

Hilmerson Safety Rail System™

- Minimal components

- Quick, easy installs

- Reuse & re-rent for 15+ years

- Self-contained kits for transport and storage

Hilmerson Barrier Fence System™

- Drop-in anchors prevent recurring damage

- Eliminates climbing footholds

- Always mounts to the same location

- Designed for longevity and repeat use

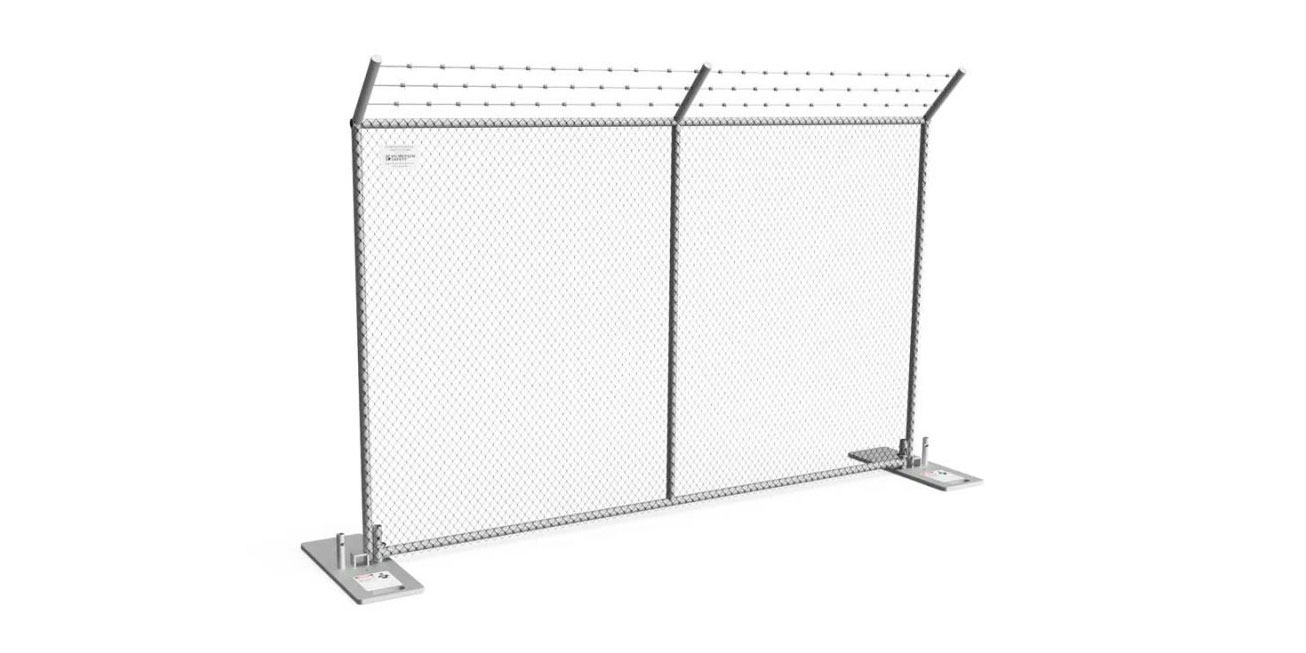

Hilmerson Free-Standing Construction Fencing™

- Heavy-duty and stable

- Clean, professional look

- Fast installs

- Lean-friendly and reusable

Unlike many safety products manufactured overseas with average-quality standards, Hilmerson’s systems are engineered from the lens of a safety consultant, construction worker, and business owner—not just a manufacturer focused on margins.

“Most of our competition aren’t safety professionals,” says Hilmerson. “They design for low cost. We design for long-term performance, safety, and efficiency.”

Real-World ROI: Reducing Waste and Increasing Value

Every contractor knows the pain of repeated spend. Wooden guardrails and disposable fencing may seem cost-effective up front, but they require constant replacement, maintenance, inspection, and disposal. Add in the uncertainty of lumber pricing—up as much as 30% since 2017—and the hidden costs stack up quickly.

Hilmerson’s systems are designed for reuse, often paying for themselves in as few as two project deployments. For companies looking to standardize safety practices across multiple job sites, that’s a compelling value proposition.

And it doesn’t end there. The lean design of Hilmerson’s systems supports 5S methodology and helps reduce material waste, labor hours, and logistical headaches.

Looking Ahead: Certainty in the Face of Uncertainty

Tariff policies may continue to shift. Materials may fluctuate in cost and availability. But when you bring production in-house, invest in durable assets, and partner with American-made manufacturers, you give your business the greatest chance to thrive.

That’s the Hilmerson difference.

Predictability. Protection. Performance.

Interested in Learning More?

Register for the upcoming AGC webinar, Taming Tariff Troubles: Risk Mitigation Strategies for Managing Tariff Impacts, happening Wednesday, April 16, 2025 at 2:00 p.m.. This session will dive into procurement strategies, documentation techniques, and creative approaches to managing project risk in a tariff-heavy environment.

Or, contact Hilmerson Safety today to learn how our American-made safety systems can help you take back control of your budget, your timeline, and your job site safety.

About Hilmerson Safety

Hilmerson Safety® is a full-service safety product design and manufacturing company serving the construction industry. Since 2001 Hilmerson Safety® has been working with construction industry leaders and contractors to develop safe, lean, construction-grade™ products and solutions that add to the company’s bottom line.

For more information email us or call (952) 239-0125