Roof fall protection is crucial for a range of reasons from protecting construction workers from falling over leading edges, to long-term protection for any person who gets access to the roof, or even for protecting skylights that could be a fall hazard.

You Need Roof Fall Protection That Lasts

When choosing a safety rail for your roof fall protection, opt for a durable solution that can withstand the test of time without experiencing issues like rust or deterioration.

The Problem With Powder-Coated Yellow Guardrails for Roof Fall Protection

Most safety rails are powder-coated steel which leads to rusting. The challenge with these lightweight 16–18-gauge steel powder-coated yellow guardrails is that they are only powder-coated on the outside. They are marketed as durable, but they are raw steel on the inside and are not designed to meet the rigorous construction environments found in today’s job sites.

The main problem often occurs when the guardrail connects to the base. Rain, snow, or condensation collects water. When raw steel is left in wet conditions, it starts to rust. Rust leads to holes, and that’s bad for your fall protection system. The challenge is this degradation may go unnoticed as it remains concealed. You only see the corrosion if you pull the pin and lift the guardrail from the base.

Why Hot-Dipped Galvanized Guardrails are the Best Choice for Roof Fall Protection

There are two types of galvanized guardrails: Hilmerson Safety Rail System™ is hot-dipped inside and out, while there are also pre-galvanized guardrails.

With hot-dipped guardrails, weep holes are pre-punched into the guardrail, and the guardrail is then submerged in zinc and coated inside and out. The benefit: this is the most durable and long-lasting guardrail in the marketplace.

Pre-galvanized guardrails are built from a pre-purchased pipe that is galvanized on the outside only.

Many companies buy steel guardrail systems just to meet the minimum OSHA requirement and keep costs down. The thing is, if you choose a powder-coated system, it might need replacement in 2, 5, or even 10 years, depending on conditions and the quality of the coating. Hot-dipped galvanized systems could be up to 20% pricier, but they can last five times as long, if not more, offering you a bigger ROI.

The Best Hot-Dipped Galvanized Guardrail: The Hilmerson Safety Rail System™

Time is money… so we designed the Hilmerson Safety Rail System™ for rapid and simple installation.

With minimal components, a user-friendly design, and self-contained kits, it’s all about simplicity and ease. Cut down on labor hours, ditch the need for ongoing maintenance, and say goodbye to rusting and the potential liability that comes with powder-coated yellow safety rails.

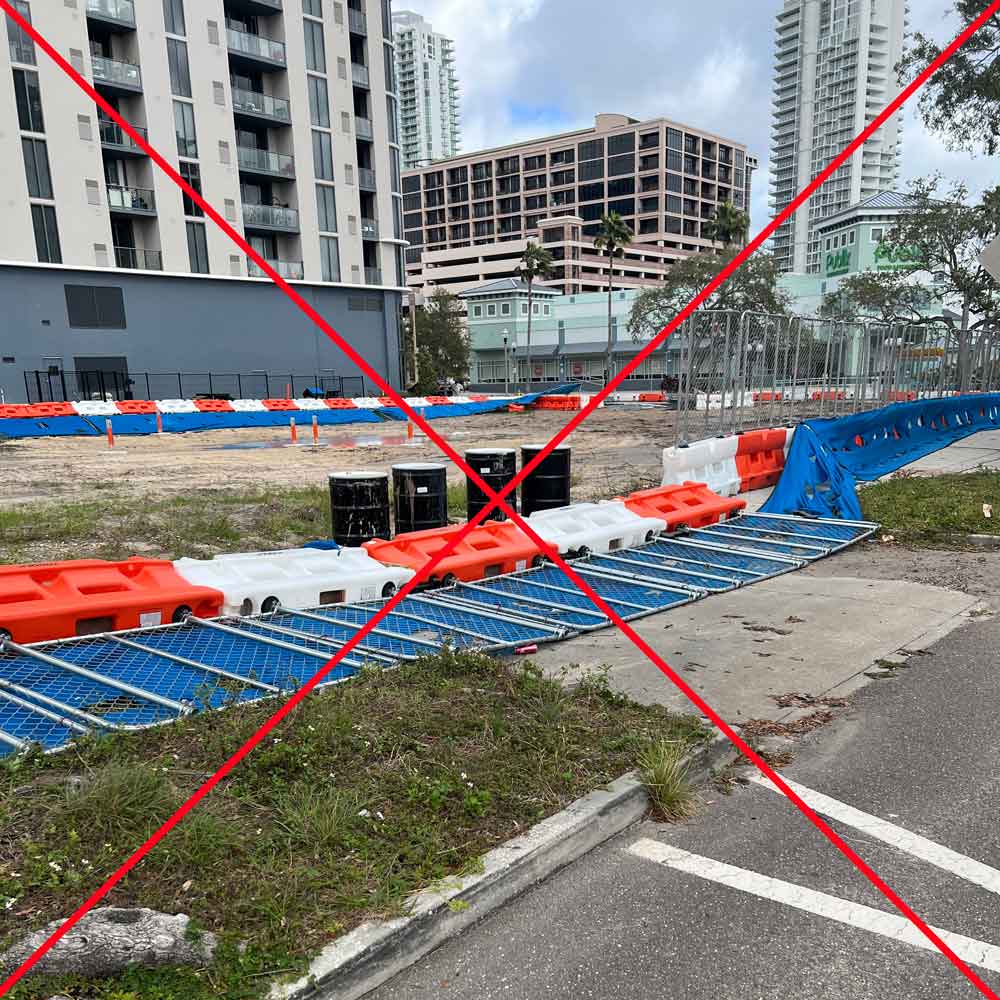

Check out our time-lapse videos of construction safety rail system installation, and picture the labor hours you could save using our system for fall protection, pedestrian control, managing access around equipment, trenching, and excavations.

About Hilmerson Safety

Hilmerson Safety® is a full-service safety product design and manufacturing company serving the construction industry. Since 2001 Hilmerson Safety® has been working with construction industry leaders and contractors to develop safe, lean, construction-grade™ products and solutions that add to the company’s bottom line.

For more information email us or call (952) 239-0125