Recognizing potential fall risks is just one way of maintaining a safe workplace, and it’s crucial to understand the OSHA guardrail requirements to guarantee compliance on your job site.

When choosing a guardrail system for your job, it’s important to pick one that is OSHA-compliant.

Hilmerson has created the Hilmerson Safety Rail System™ to meet all local and national codes, regulations, and industry best practices. Our guardrails follow all OSHA Guardrail Requirements and make it easy to install guardrails while being compliant.

OSHA Guardrail Requirements for Construction

OSHA has specific requirements for construction that include the installation of guardrails at heights of 6 feet or more, and 4 feet or more for general industries.

If an employee is reaching 10 inches below the walking or working surface, then fall protection is required, like a guardrail. For projects utilizing wire rope as a guardrail system, it’s essential to place flags every 6 feet or less along the length.

Summary:

- Guardrails are required at 6 ft. in construction and 4 ft. in general industry.

- Fall protection is also required if a worker reaches 10 inches below the surface.

- Wire rope systems must have flags every 6 ft. for visibility.

General OSHA Guardrail Requirements

OSHA’s general guardrail requirements apply to many applications, from leading edges to loading docks to rooftop skylights. For general guardrail requirements, all protection is needed for any structure or platform measuring 4 feet or higher above the ground.

However, when working above hazardous equipment, regardless of how high above the ground, OSHA requires that fall protection be used.

Summary:

- Applies to leading edges, loading docks, skylights, and more.

- Guardrails are required for platforms 4 ft. or higher.

- If working above hazardous equipment, fall protection is required at any height.

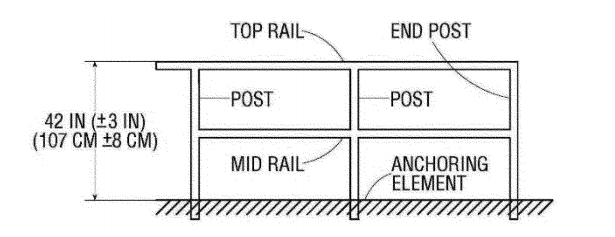

OSHA Guardrail Requirements for Size

Hilmerson guardrails always follow OSHA-specific guidelines to ensure safety. These guidelines include a 42-inch height for the top rail, with a small allowable range of plus or minus 3 inches. It is important to note, some State Plan requirements for height compliance do not allow the plus or minus 3 inches. Hilmerson safety rails are specifically 42″ for that reason and are compliant across all states.

We offer a variety of guardrail options in terms of size and width, and you can explore all our different guardrail kits on our Kits and Applications page to find the perfect fit for your needs.

When exposed to falling objects a toeboard is required. Toeboards are required to maintain a force of 50 pounds in any down or outward direction and shall be a minimum of 3.5″ in vertical height from the top edge of the walking/working surface with no more than a quarter inch gap from the bottom of the toeboard to the walking/working surface.

Hilmerson safety rails have an integrated toeboard engineered in the system.

Summary:

- Top rail height: 42 inches (+/- 3 inches).

- Midrail: 21 inches from surface, no gaps over 19 inches.

- Toeboard: 3.5 inches high, withstands 50 lbs. of force.

- Hilmerson rails are manufactured at exactly 42 inches for nationwide compliance.

How Strong Do Guardrails Need To Be?

Hilmerson guardrails not only meet but also exceed OSHA standards for safety.

Top rails are designed to withstand 200 pounds of force without bending below 39 inches, ensuring your protection. Midrails are also built to handle 150 pounds of force in both outward and downward directions.

Our guardrails are constructed with galvanized heavy-duty 13-gauge steel, making them exceptionally robust and safe. You can trust that our guardrails not only meet OSHA requirements but go above and beyond to provide the highest level of protection.

Summary:

- Top rails: withstand 200 lbs. of force, can’t bend below 39 inches.

- Midrails: withstand 150 lbs. of force.

- Hilmerson rails: engineered with galvanized 13g steel — stronger than OSHA minimums.

Passive Guardrail Installation: Why It Matters

Even the best guardrail system won’t protect workers if it’s not installed correctly. OSHA requires that guardrails withstand a 200-pound down-and-out force, but that compliance depends on proper installation in the field. One of the most common mistakes we see is forgetting the counterbalance. Every passive guardrail run needs a minimum of five feet of guardrail on each end to stabilize the system. Without that, it can be pushed right over the edge — creating a hazard instead of protection.

On jobsites across the country, we’ve seen guardrail systems — both Hilmerson’s and competitors’ — installed improperly. Too often, crews assume “close enough” is safe enough. It’s not. These shortcuts put lives at risk. That’s why OSHA requires a competent person to oversee fall protection.

Training Crews for Compliance and Safety

To prevent these mistakes, Hilmerson goes further than just selling a product. We provide free training to ensure every guardrail is installed properly. We’ll bring a truck and trailer, meet your crew onsite, and train your people step by step.

For added support, we’ve built animated installation videos you can watch anytime. If you can see it, you can install it. Our system is designed to be simple — but if it’s set up wrong, it can be dangerous. That’s why training and oversight matter.

We want every contractor to be confident that the guardrails protecting their crew are installed correctly. A guardrail system is only as safe as the way it’s installed.

Miscellaneous OSHA Guardrail Requirements

Make sure your guardrails also follow these miscellaneous requirements:

- No projection, laceration, or puncture hazards.

- Components should have a minimum thickness or diameter of 1/4 inch.

- Guardrails should prevent clothing from getting caught.

- Avoid using steel or plastic banding for guardrails.

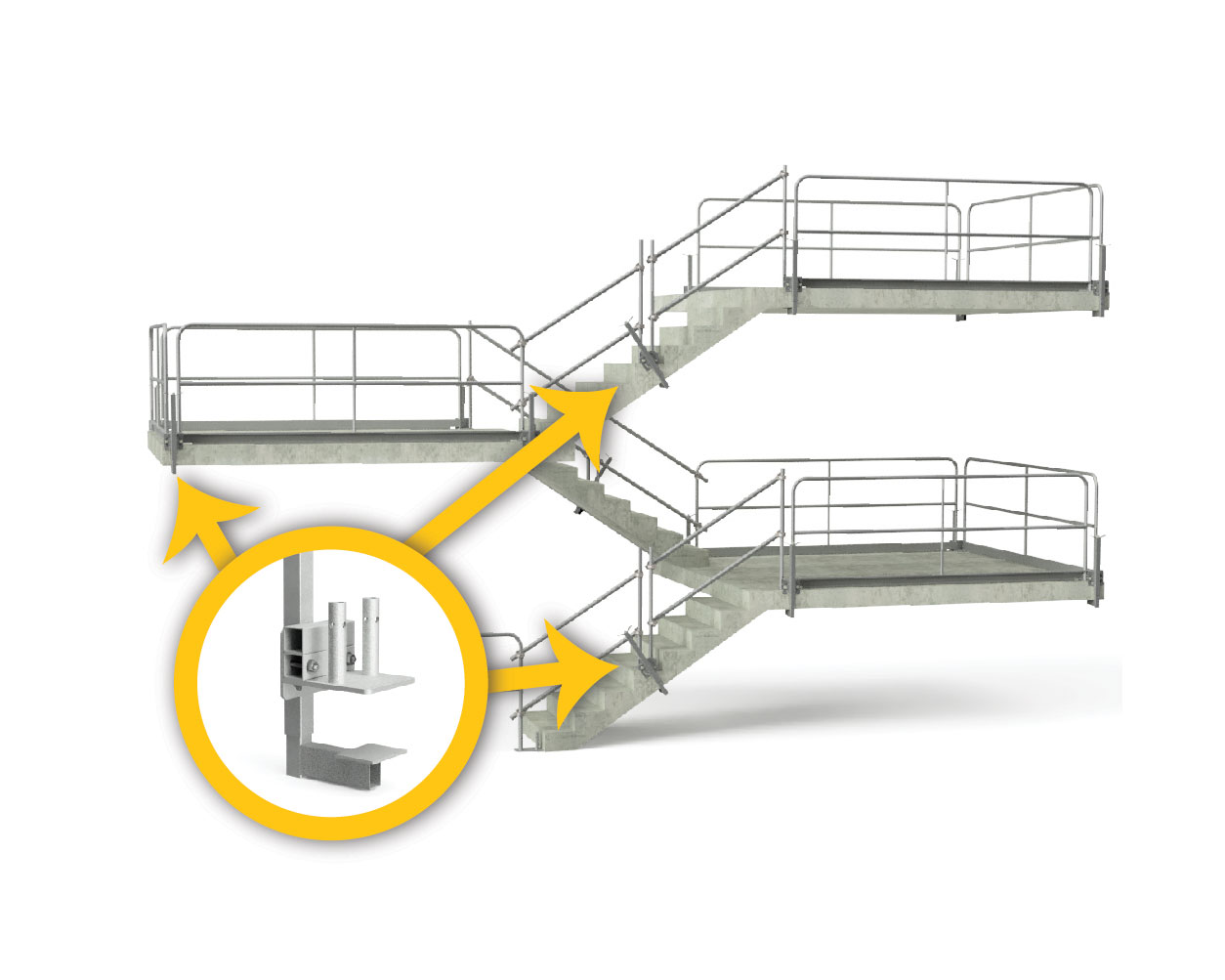

OSHA Stair Guardrail Requirements

Any landings that are 4 feet or more in height require the installation of a guardrail system to prevent falls. Similarly, for stairs with four steps or more, OSHA mandates both a stair rail system and a handrail system.

At Hilmerson, we offer our own OSHA-compliant Temporary Guardrail Configurations for Leading Edges, Stairs, Slabs, and Rooftops. Additionally, we’ve developed a custom-designed multi-use stair/slab grabber.

Summary:

- Landings 4 ft. or more must have guardrails.

- Stairs with 4 steps or more require a stair rail system + handrail.

- Hilmerson offers OSHA-compliant temporary stair/slab grabber systems.

FAQs About Guardrail Safety

Construction Laws and Regulations – Occupational Safety and Health Administration

Safety Rail System Kits & Applications

Hilmerson Safety Rail Systems are built with American steel, designed by safety experts, and engineered to be simple, tough, and compliant. From rooftops, stadiums, and leading edges, our systems provide rock-solid fall protection.

To learn more about OSHA guardrail requirements, visit OSHA’s website.

Born in the Field. Made in America.

At Hilmerson, we don’t take shortcuts — and neither should you. Our guardrails not only meet but exceed all OSHA guardrail requirements, and they’re backed by free training. As construction safety professionals, we know that complex or difficult safety rail systems make it easy to take shortcuts or install a system incorrectly. That’s why we designed the Hilmerson Safety Rail System™ to be as simple as possible with limited components, zero mechanical parts, and engineered to exceed OSHA requirements. Learn more about the Hilmerson Safety Rail System™ here.