Purchasing a Safety Rail System? – Here’s 5 Features That Save Labor Time & Reduce Risk

Safety people understand the need to “keep it simple”. We don’t want to see complicated systems on the job with lengthy installation instructions. To keep systems like safety rails error proof and injury proof they should be easily installed in a few basic steps. This leaves less room for error, less room for human short cuts, and assurance that your investment is installed properly and safely. Here’s 5 safety rail system features that can save labor time and reduce risk:

Minimal Tools Required

During our 30 years as safety consultants we encountered all types guardrail systems for construction. Some had elbows, some required tools like hammers, Allen wrenches, and saws. Some had ratchets, springs, threaded rods or special keys that you had to keep track of. Some required ceilings or hot work permits. Others had green and red light indicators. All of which were unnecessary and complicated for the installer. If a tool is forgotten or an important step missed the result can be injury or OSHA violations. Look for a system with minimal components. Hilmerson’s weighted base guardrail system is installed with a mobile dolly. No tools required. Our penetrating base guardrail system only requires a hammer drill.

Weighted Base Install

Anchored Base Install

Movable Kits

Labor cost should be taken into consideration when comparing safety rail system cost of investment. Many systems require 3-4 laborers to complete an installation and move around the job site and can take a significant amount of time to install in comparison to other systems. Look for a safety rail system in a “kit” style. Safety rail kits can be easily moved, stacked and stored and can be quickly installed by two or less laborers.

Engineered for Quick Installation

Most guardrail systems are too technical in nature, requiring complex directions. We’ve seen safety rail systems delivered with book length manuals. Some even requiring specialized training off-site and even in other countries. Make it easy on your team. Look for an engineered system that can be installed in a few easy steps.

Low Maintenance, Easy to Inspect

Rust causes liability. Where a guardrail system typically corrodes and fails is where the rail goes into the base. Powder-coated rails are the biggest offender. Most midrails are pinched when connected to the vertical legs and the posts of the safety rails sit inside the base. Water often pools in this area causing a significant risk for corrosion. Look for a durable system that is hot-dipped galvanized and coped, not pinched. Our robust safety rail system is built to lasts 15+ years. Our guardrail is installed over the base prong, not inside so there is no place for water to pool. This also allows for simple inspection. There is no need to pull off the safety rail from it’s base to see if there is rust and corrosion.

“We found that we can quickly do an inspection to see if they (Hilmerson safety rails) are installed properly. And our crews were immediately more productive since they spent less time fixing and adjusting guard rails.” – Taylor Gunkel, Superintendent & Design Phase Manager, Mortenson

Pinched Safety Rail System. Rust & corrosion at base.

Integrated Addons

Most guardrail systems require you take an additional step to add on optional features like a toe board. This requires more labor time and more room for error. Look for a complete system that has these features built in or engineered attachment options that will help serve all scenarios on the job site.

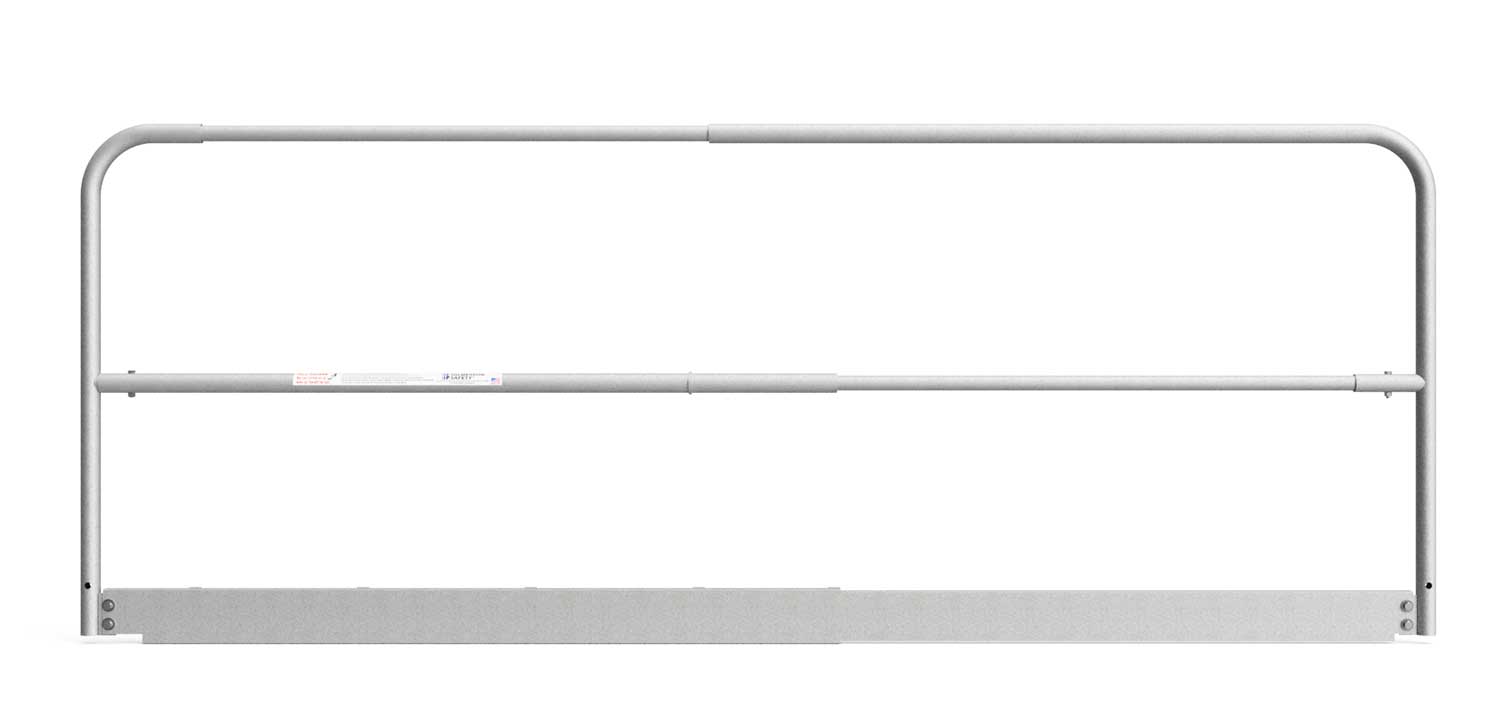

HLM-GR9AG

Safety Rail Panel 5.5ft – 9ft: (Adjustable w/ integrated toe board) 1 ⅝” O.D. x Galvanized 13 gauge tube. Weight: 77 lbs.

About Hilmerson Safety

Hilmerson Safety® is a full-service safety product design and manufacturing company serving the construction industry. Since 2001 Hilmerson Safety® has been working with construction industry leaders and contractors to develop safe, lean, construction-grade™ products and solutions that add to the company’s bottom line.

For more information email us or call (952) 239-0125