A common belief is that success favors those who are active rather than passive.

Hitting things head-on and hard directs the outcome while being passive leaves you vulnerable. When it comes to construction safety, in particular fall protection, we often find the exact opposite to be true.

Active vs Passive Fall Protection

As safety professionals, we describe safety systems as either “active” or “passive” to identify the type and amount of interaction required by the worker.

Active systems include personal fall arrest equipment, while safety nets and guardrails are considered passive systems. Where fall hazards exist, OSHA-compliant options for employers include personal fall arrest systems, safety nets, administrative controls (fall protection plans), and engineered guardrails.

Are Active or Passive Fall Protection Systems Better?

Success favors those who pursue solutions based on the acronym KISS—Keep It Simple Stupid! The fewer moving parts, inspections, and decisions that need to be made by the worker, the better.

Why are Passive Fall Protection Systems The Best Choice?

Asking a worker to properly use all of the components of a personal fall arrest system can be challenging. We see this often with decisions involving connecting to suitable anchor points or determining necessary clearance distances to ensure a worker doesn’t hit the ground before fall arrest equipment stops them. In situations where a passive guardrail system can be used, it allows a “set it and forget it” application of fall protection. This protects everyone within that work zone. Combating human error with the use of simple passive solutions provides the greatest degree of risk reduction.

Guardrails For Passive Fall Protection

Guardrail systems have been around well before the advent of workplace fall protection standards. Things employers should consider when choosing the type of guardrail system include:

- Ease of installation—the labor effort and cost associated with setting up, moving, and removing the guardrail system.

- Drop protection—guardrails not only protect workers but also prevent debris and tools from becoming threats by the use of debris netting and integrated toe-boards.

- Tools required – use of circular saws, nail guns, and other power tools exposes workers to additional risk of injury and additional drop hazards on leading edges.

- Maintenance and repair—how much repair or maintenance of the guardrail will be required over the life of the project and future projects?

- Reuse—can the components be reused or will the material be discarded resulting in new material purchase and disposal costs?

- Life-cycle—is the guardrail system subject to being easily damaged, rust, or wear

- Handling—are the components packaged to be easily moved or are they lose requiring significant handling?

- “Green” solution—does the guardrail system align with a corporate environmental-friendly approach to the construction process

The Hilmerson Safety Rail System™ is an innovative guardrail system designed specifically to meet the challenges of the construction industry.

The Problem:

Wooden Guardrail Systems

The Solution:

Hilmerson Safety Rail System™

Fast and Simple Safety Rail Installation for Construction

Weighted Base Install on Rack | Hilmerson Safety Rail System™

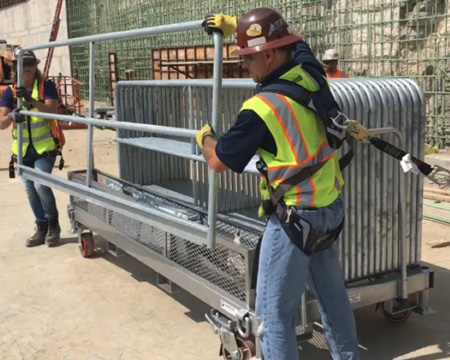

Anchor Base Install on Cart | Hilmerson Safety Rail System™

Weighted Base Install w/ Cart | Hilmerson Safety Rail System™

Get Pricing

Find out how much you can save using the Hilmerson Safety Rail System™.